Positive Displacement Blowers

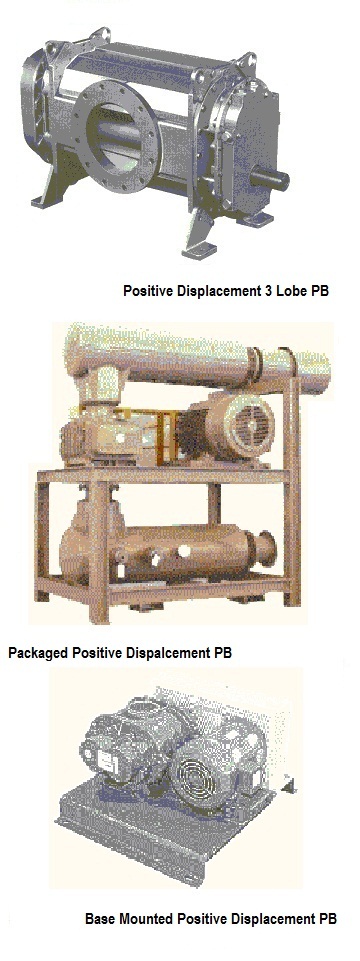

High pressure PD blower delivers up to 15,000 SCFM of uncontaminated, oil free gas flow at up to 18 PSIG pressure, or from 30” to 0” Hg vacuum . Typical applications include air conveying and palletizing, kiln curing and drying, product sterilizing and heating, sparging of liquids; in steam generators, air-water separators, aerators; for soil remediation, agitation, flotation, vacuum technologies, and all applications requiring medium pressure, or vacuum.

PD pressure blowers are available with cast, or fabricated steel casing enclosing Two-lobe, or Tri-lobe rotors synchronized by timing gears. ANSI class 125/150, or DIN, ISO flanges are standard. All PD pumps are available in horizontal, or vertical airflow orientation. Slinger Oil Seals in splash oil lubricating sump compartment and air seals in piston / blower lobe compartment are standard. Average design life is 100,000 hours.

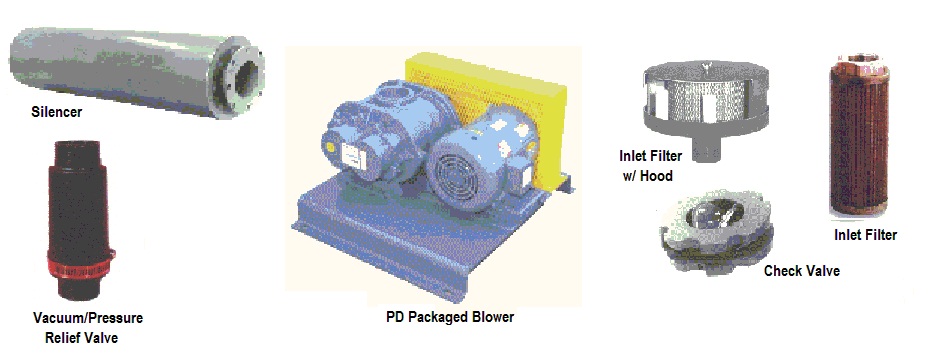

Pressure blower PD packages are supplied on unitary base of standard or isolation type with spring or RIS rubber-in-share vibration isolators. Power transmission is implemented by V-Belt Drives complete with V-belts, adjustable or constant speed sheaves and pulleys, QD-bushings, and motor slide bases; or by direct drive coupling. Motors are of High Efficiency design, controlled by Variable Frequency Drives. OSHA Belt Guard and OSHA Coupling Guard are standard.

Expansion Joints, Flexible Connectors and Compression Couplings isolate PD pump to allow for thermal expansion and mis-alignment of piping. Flexible hose of flanged/ slip-on-clamped type is used for up to 5” Sch. 40 pipes. Single-Arch Expansion Joint is for flanged connections. Compression Couplings allow for limited thermal expansion.

Pressure / Vacuum Relief Valves are of spring loaded type kunkle valve, and weighted type. These safety valves set-up point of operation for PD system and bleed-off to prevent over-pressurization, or relief vacuum.

Inline Check Valves direct airflow or vacuum in one direction only and prevent back flow in PD system.

Pressure/Vacuum Controls include differential pressure gauge up to 15 PSIG, vacuum gauge from 30” to 0” Hg, temperature gauge, gauge snubber to reduce pressure pulsation, and .25” pet-cock valve to isolate the gauge.

PD Blower Silencers are offered as inlet and discharge silencers of Chamber Type, Chamber Absorptive Type, and Absorptive Type. Sound Enclosures are custom made based on application requirements.

Inlet Filters are offered with wire-mesh oil wetted (multi-wash), high efficiency ultra-synthetic (polyester, washable), or paper (thrown away)media. Controls included Differential Filter Pressure Gauge used as Filter Restriction Indicator. Filter casing is available as open flange design, hooded design, or combined filter-silencer assembly. In-line filters are custom.

Controls: VFD drives, Across-the-Line Starters, Flow-Pressure-Meters - complete control system supplied in NEMA 1, NEMA 3R, NEMA 4 enclosure.