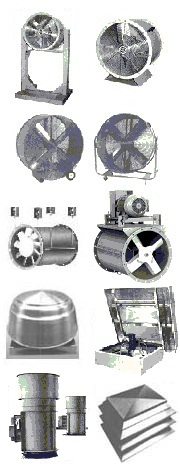

Industrial axial wall

fans,

blowers, ventilators, high temperature wall fans and blowers,

centrifugal

radial high pressure blowers, roof / wall exhaust and supply fan

ventilators, OEM centrifugal blowers.

FANS MALL

Wall Fans

FANS MALL

Wall Fans

Propeller fans are used primarily in industrial facilities to supply filtered air to spaces housing personnel and electrical and/or electronic equipment. Available in 'draw-thru', or 'blow-thru' configuartions, with removable filter housing cover and easy-clean filters.

American Blower axial flow panel fans are designed for low pressure building ventilation, room ventilation, industrial ventilation, commercial ventilation and industrial process application. Typical applications include heat, smoke, and fume removal; process ventilation and process air handling; proces drying with ambient or preheated air; comfort process cooling and general ventilation of buildngs. Available in direct drive arrangement 4 and corresponding belt drive arrangement 9. Sizes from 6 thru 96. Capacities: to 350,000 CFM. Static pressure to 2.5 inches water gauge.

Filtered Supply Fans are axial fans with cast or adjustable pitch aluminum impellers. These units are designed to provide filtered outside air to buildings such as manufacturing plants, warehouses and auditoriums. Filtered Supply Fans are also available in stainless steel and other special materials.

Spark Resistant X-proof fan construction: wall fan for non-sparking x-proof applications is supplied in AMCA A (all aluminum or monel airsteram), AMCA B (aluminum wheel, or monel wheel), or AMCA C (buffer type) spark resistant construction. For AMCA A applications wheel is made of non-ferous material with monel shaft and special x-proof motor.

Canada Blower high temperature fan construction: wall fan is avaialble in high temeparture construction with high temperature motor and steel prop, or stainless steel prop.

Corrosion resistant construction and chemical duty construction: for corrosive environment wall fans are avaialble in 304 SS, 316 SS, or 316 L stainless steel construction. For chemical process applications wall fans are available in fiber reinforced plastic (FRP) construction, or in polypropylene construction, or in plastic.

Wall fan accessories: wall housing, wall cabinet, heavy gauge housing, extended wall housing, wall housing access door, inlet guard, outlet guard, caged guard, fixed louver, shutter, manual shutter with pull chain and quadrant lock, gravity automatic shutter, motorized shutter, back draft damper, shutter motor, BELIMO motor, NEP motor, Multiproducts motor, Delay switch, Speed controller, VFD, intake hood, discharge hood, weather hood, hood bird guard, hood bird screen, insect screen. Controls and drives: pressure switch, end switch, electrical damper motor, delay switch, pneumatic actuator, speed control, vfd control, motor starter, carbon monoxide sensor, oxygen sensor, electronic gas sensors and others.

Call

us today: 1-866-225-6937 E-mail: blower@industrialpressureblower.com

Canada Blower BP panel fan is designed for general ventilation and process cooling involving the movement of clean, ambient temperature air. Typical Canada Blower fan applications include air filter units, casting cooling, cold room circulation, condensation control, electrical panel & transformer cooling, elimination of heat stratification, greenhouse ventilation, non-corrosive fume exhaust, parking garages, and washed parts drying.

High temperature fans, industrial process pressure blowers, high pressure side channel regenerative pressure blowers; industrial; process and commercial heating; ventilating and air conditioning equipment.

An exhaust fan is a mechanical ventilation device that helps to draw out stale and impure air from your home and bring in fresh air, thereby improving the quality of indoor air. Exhaust fans are typically ducted to the exteriors of your house, through which bad indoor air can effectively be removed from your living space.

Exhaust fans are very effective at any building ventilation. Without proper ventilation, the air inside your home can get filled with harmful contaminants and disease causing pathogens.

Exhaust fans are classified into various types, mainly depending on the type of mount and the location where you need to install the fans. The different types are:

1. Ceiling Mounted Exhaust Fans: As the name suggests, ceiling exhaust fans are those which are installed in the ceiling. Such fans expel stale air from your home upwards through the roof. The fan is connected to ducting, which is exhausted outside the home via an external vent, like a roof cap or soffit exhaust vent.

2. Inline Exhaust Fans: Unlike ceiling exhaust fans that are installed directly into the ceiling, inline exhaust fans are typically mounted in-between ducting, hence the name inline fan. For instance, if you wanted to ventilate an area that did not have clearance or space for a ceiling mount fan, you would make use of inline exhaust fans to ventilate such areas. The exhaust fan would be placed in between the ductwork and the stale air would travel through the ducts and ultimately be expelled from your home. Since inline fans are not mounted directly to the ceiling, they are very quiet. When installing an inline fan, to reduce noise, we recommend using an insulated flex duct that is at least eight feet long from the intake port on the ceiling to the inline fan.

Inline exhaust fans are ideal for exhausting areas or rooms where you cannot, or do not wish to install the exhaust fan directly. Since these types of exhaust fans are mounted in remote areas, they are also referred to as remote mounted exhaust fans. Inline exhaust fans can either be single-port (exhausting from a single area) or multi-port (exhausting from multiple areas).

3. Wall Mounted Exhaust Fans: These exhaust fans are installed on walls. Since they are installed on exterior walls of the home and not on interior walls, the stale air has a direct route to the outside of your home and thus no duct work is required in installing these exhaust fans.

4. Combination Exhaust Fans: Exhaust fans are also available as combination units. You have the choice of a fan-light combination where the exhaust fan provides illumination as well, or heat-fan-light combination wherein you get a heater, light and ventilating fan all in a single device.

5. Exterior Remote Mounted Exhaust Fans: While most other exhaust fans are installed inside your home and push stale air out, exterior remote mounted fans are installed outside your home and pull out stale indoor air instead of pushing it out. The main benefit of these exhaust fans is that regardless of however noisy they are, most of the noise remains outside your home.

6. Kitchen Range Exhaust Fans: These fans are mounted inside the range hood over your kitchen stove. Such fans not only help to rid your kitchen of stale air but also help to expel bad odors and reduce moisture levels in your cooking area.

These several types of exhaust fans can be used for complete ventilation of your bilding including intermittent local ventilation for baths, kitchens, dryer rooms; continuous whole building ventilation, and for exhausting hard-to-air spaces such as crawl spaces, attics, and basements.

ventilating.com fanblower.com highpressureblower.net industrialblowerfan.com industrialfanblower.net industrialfanblower.com pressureblower.net northernindustrialsupplycompany.com industrialpressureblower.com tenderall.com chicagoblowercanada.com cbblower.com buffaloblower.com buffalofan.com nis-co.com canadianblower.com olegsystems.com canadablower.com abbblower.com acmefan.net industrialblower.net fansandblowers.net americanblower.net barryfan.com cincinnatifan.net canadafans.com barryfan.net pennbarry.net pennfan.net tcffan.com

High temperature fans, high pressure process pressure fan blowers, regenerative pressure blowers; wall and roof exhaust and supply power ventilators, centrifugal and axial fans and blowers.