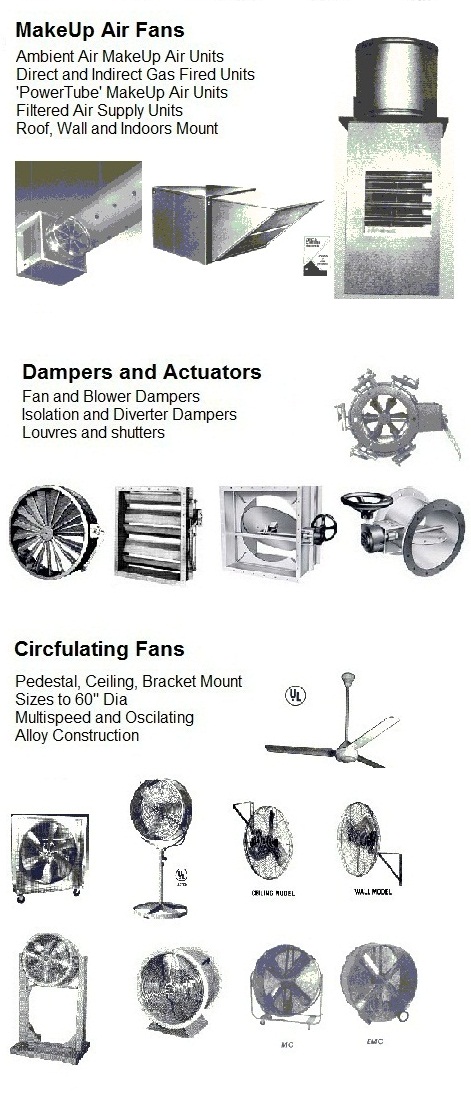

A make-up air system usually consist of a wall-mounted American Blower propeller fan coupled with an automatic shutter or an inlet weatherhood and a control system to activate the fan motor. For rooftop installations, a powered American Blower hooded roof ventilator, which may contain a motorized shutter, can be used successfully. These systems would provide make-up air mainly for ventilation purposes.

In many areas, air must be conditioned before entering a facility. This necessitates that the make-up air system have heating and often air cooling and filtering abilities. A so called make-up air unit is required. Typically a make-up air system includes an air mover section, usually a propeller or centrifugal type fan, an air tempering section containing heating and where necessary cooling and filtering equipment, and a control system.

Fan selection and power requirements are generally determined by the application. When only general ventilation is required (fan pressure requirements are low), a propeller type fan can be utilized. To supply make up air through a duct system with a resistance of 0.5 in w.g. or more, a centrifugal fan should be considered. In either system, diffusers may be used to direct the discharge air velocity.

In situations where the inside air quality is acceptable, often a portion of the inside air may be drawn back through the make-up air unit where it is recirculated back into the building. Advantages of using Canada Blower Recirculating Make-Up Air fan units are lowered heating costs, better indoor air mixing (reduced air stratification), as well as constant building pressurization.

An adequate amount of makeup air is required for personnel, machines, and processes to operate properly, efficiently, and safely. Failure to provide adequate make-up air is often the cause of unnecessary expenditures for additional exhaust systems and heating or cooling equipment. These devices in turn compound the problem of air starvation within the building. Reliable, cost effective equipment is available from Canada Blower to supply the make-up air necessary to balance air removed from a structure.

Call

us today: 1-866-225-6937 E-mail: blower@industrialpressureblower.com

Canada Blower sirect-fired gas air make-up systems offer a wide range of facility air management choices, as

well as maximum installation flexibility. Exhaust fans cannot work properly without an adequate supply of air. If provision for air supply is not made, the vacuum created reduces the effectiveness of mechanical ventilation. Negative

pressure also causes excessive infiltration, making it difficult to heat properly. These conditions can be corrected by replacing the exhausted air with clean, fresh, pre-treated air. The primary purpose of make-up air is to temper outside air and supply it in sufficient quantities to bring about the condition of balanced ventilation.

Depending upon the quantity of make-up air in relation to the exhaust, the heating system will shut down during the working day allowing the make-up air system to handle the entire load. The heating system then functions only to maintain satisfactory temperatures at nighttime and other plant shutdown periods. When you add an air make-up system to an existing plant it is necessary to make a detailed analysis of the overall situation in order to determine what the

relationship might be between the heat added by make-up air and that supplied from the plant heating system. Where exhaust systems already exist, the installation of make-up air usually will not increase the heating load and can bring about a reduction of overall heating costs. This may be understood by considering that infiltrated air, warmed at least

partially by the plant heating system, is ultimately mixed with room air and exhausted through the ventilating fans. Infiltration of unheated air results in a decline of heating efficiency. Most heating systems are not adequately rated to cope with infiltration when appreciable negative pressures exist. Air make-up units provide a systematic method of heating entering air and supplying it in controlled quantity. With the proper balance of supply and exhaust, infiltration is eliminated and negative pressures are equalized. By properly tempering supply air, the heating system

is relieved of this abnormal load. The results are uniform space heating, effective ventilation and improved comfort.

Experience with fresh air heating systems has shown that it is practical and economically sound to heat industrial plants and even warehouses with fresh air. The question of whether to use 100% fresh air or recirculate some portion is debatable, and engineers are using both methods in their applications.

When Buffalo Blower direct-fired systems were first used, some authorities felt that positive exhaust was necessary to assure a balance and prevent the possibility of products of combustion buildup. It is now generally recognized that air can be supplied into most buildings having no mechanical exhaust and in quantities sufficient to heat them without building up a positive pressure of more than a few hundredths of an inch water gauge. It is the reverse of infiltration and this principle can be used to design fresh air plant heating.

The standard air make-up unit is used for industrial space heating with 100% outside air or with a fixed percentage of recirculation and in some designs with a combination of these. Your Aerovent sales representative can assist you in determining application requirements for general air make-up and for fresh air heating. They can supply detailed information as it may apply to specific conditions.

Model ADH – Buffalo Blowers’s Automatic Door Air Heater tempers the sudden influx of cold air when a rolltop or overhead door is opened. To mix hot and cold air, it is necessary to create a highly turbulent condition directly in front of the door. The Door Air Heater provides a high velocity blast of hot air to mix with the sudden influx of cold air, “bore through it” and splash off the floor. Installed at a car wash exit, the ADH Series of door air heaters directs high-speed air to help dry vehicles after a drying cycle. Typical applications include logistics terminals, industrial manufacturing and car wash.