Canada Blower BD roof ventilator is a versatile, high discharge fan. This ventilator features a taller design than typical centrifugal or propeller roof ventilator fans and is especially useful in the discharge of smoke and / or fumes high above the roof line and away from surrounding ventilation systems. Three part assembly consisting of stack cap, fan section and base. Features cast aluminum airfoil blade propeller. Standard Canada Blower fan construction is heavy-gauge steel finished with air-dried gray enamel. Hot dipped galvanized, stainless steel or all-aluminum ventilator construction are optional.

Low Profile Canada Blower Hooded Roof Ventilators provide cost effective, general purpose ventilation solutions for commercial and light industrial ventilating applications. The aesthetically pleasing modular hood design minimizes extension above the roof line. Both direct and belt driven fan models are available in exhaust and supply configurations. A wide array of adjustable pitch, cast aluminum ventilator propellers are available to meet specific fan performances and application requirements. Canada Blower also offers a complete line of ventilator options and accessories such as roof curbs, backdraft dampers, disconnect switches and special coatings to maintain single source responsibility.

A simple roof ventilator is essentially an opening in the roof with a cover to keep out rain and to prevent winds from interfering with its functioning. Natural convection is an appreciable aid to ventilation in a large building only if it contains sources of large amounts of heat. A further useful adjunct is a fan fan, device for agitating air or gases or moving them from one location to another. Mechanical fans with revolving blades are used for ventilation, in manufacturing, in winnowing grain, to remove dust, cuttings, or other waste, or to provide draft for a fire. The addition of distribution ducts to the fan and a system for forcing air into the building provides greater efficiency. Outlets are designed to attain maximum mixing of air and to move large amounts of air at low velocity so that temperature layers are eliminated. Factories have special suction hoods and enclosures to draw away localized dust, fumes, and heat. Incoming air may be cleaned of dust by filters or electrostatic precipitators.

Deep mines, underwater tunnels, and other subterranean and submarine environments require elaborate mechanically operated systems for maintaining the air supply in a healthful condition. The lives of those working in, or traveling through, such areas depend upon a constant supply of fresh air; not only must the systems used be highly efficient, but there should be provision for emergencies in case of failure of the apparatus in operation. An outgrowth of studies of problems of ventilation is the development of methods of air conditioning heat pump is a reversible device that does mechanical work to extract heat from a cooler place and deliver heat to a warmer place. The heat delivered to the warmer place is, approximately, the sum of the original heat and the work done.

Such ventilation systems, unlike ordinary methods of ventilation, are independent of outdoor atmospheric conditions and can, therefore, maintain the indoor atmosphere at the most healthful temperature and humidity and can free the air of dust and other undesirable materials. They accomplish this, however, at a considerable cost in energy.

Roof ventilators are another option. They work in both summer and winter. In summer, roof ventilators reduce the build up of heat in the ceiling spaces, reducing the heat load on your insulation, meaning that the insulation works more effectively. In turn, you will save on your electricity bills as the air-conditioning systems will not have to work as hard. In winter, it reduces the amount of condensation that forms when warm, moist air from exhaust fans meets cold surfaces. Roof ventilators will also reduce the amount of corrosion and timber that occurs because of condensation. Roof ventilators should be installed where there is sarking underneath tiled roofs, when metal deck roofing is used, and when there is evidence of condensation in the roof spaces or ceilings.

Call

us today: 1-866-225-6937 E-mail: blower@industrialpressureblower.com

Industrial & OEM fans, blowers, ventilators, pressure blowers and high temperature fans. Sales of centrifugal & axial fans and blowers, industrial process fans, building ventilators, dust collecting fans. Supplier of radial blowers, vaneaxial & tubeaxial ventilators, explosion proof spark-resistant fans, fiberglass FRP, PVC and Propylene blowers, oven circulating super high temperature fans. Designers of air tight sealed blowers, stainless steel, aluminum and special alloy fans, super high pressure centrifugal, regenerative, side channel and multi-stage blowers, high volume ventilators. Engineering of air moving and industrial ventilation equipment, combustion blowers, material handling and pneumatic conveying fans, inline direct & belt driven ventilators. Distributors of Chicago Blower, American Coolair / ILG NYB TCF fans, wall & roof exhaust and supply power ventilators, panel propeller fans, gas-fired direct and indirect make-up air handling units AHU, air curtains and blow-off air knives and air-knife systems, fan silencers, corrosion-resistant ventilators, positive pressure ventilators, mobile macoolers, reversible duct ventilators, fan dampers and louvers.

An economical in-line fan design - Canada Blower Mixed-Flow Fans.

Buffalo Blower RREH Three-Way Heat Saver / Ventilator is a multi-purpose fan designed for ventilating applications that require air recirculation. Buffalo Blower reversible fan and versatile damper control systems make a unique year-round ventilator capable of operating in three different modes: Heat Saver Mode, Mixed Air Mode, and Exhaust / Supply Mode.

Each Buffalo Blower ventilator is constructed with close tolerances between the fan propeller tips and the orifice to maintain maximum efficiency. The reversible, cast aluminum alloy fan propeller is secured to the motor shaft with a split taper lock bushing. The hood of the Buffalo Blower Three-Way Heat Saver / Ventilator is constructed of corrosion-resistant, fiberglass reinforced polyester and is attached to the fan with heavy-duty structural angle supports for added fan stability.

Typical Buffalo Blower Three-Way Heat Saver Fan Configuration features:

• Hooded inlet

• Motor operated recirculating dampers

• Direct drive reversible panel fan

• Plenum section

• Prefab insulated fan curb (optional)

• Modulated supply fan damper (optional) to mix outside air with recirculated air

• Modulated temperature control (optional) to temper recirculated air with outside fresh air.

Buildings with high ceilings save on energy costs by using the Three-Way Heat Saver configuration. During the winter, heated air inside the building rises to the ceiling where it becomes trapped. Air temperatures near the ceiling may be 5°F to 20°F higher than temperatures at the floor in the working area. Due to convection, the heat is transferred to the exterior side of the ceiling. This causes the building to lose heat. To compensate for this heat loss and maintain a uniform temperature, the building’s heating system must continually work at maximum levels. By installing the Buffalo Blower Heat Saver unit, the warmer air at the ceiling is recovered and directed to the working area. As standard, the unit is furnished with recirculating dampers on two sides of the plenum fan section. The unit recirculates the air by inducing it through the recirculating dampers and directing it back to the floor level. Recirculating the heated air minimizes the transfer of heat through the building’s ceiling and reduces the energy load on the building’s heating system. By recycling the trapped warm air, a manufacturer can expect to save 10 to 30% on fuel bills. In areas where high heat loads occur, Buffalo Blower Three-Way Fan Heat Saver / Ventilator can operate in the mixed air mode and mix the recirculated air with outside air to maintain a comfortable working environment.

Heat Saver Mode – In the heat saver mode the unit induces warmer air trapped near the ceiling through the recirculating dampers and directs it downward to the working area. Recirculating the air in this way reduces the load on the heating system by maintaining a nearly uniform temperature between the floor and the ceiling.

Mixed Air Mode – The optional modulating fan damper control system permits outside air to be added to the recirculated air. This is particularly desirable in spring and fall when wide outside temperature fluctuations can cause the heating system to override.

Exhaust Mode / Supply Mode – With the recirculating fan dampers closed, the ventilator can be used to exhaust hot air from the ceiling area. By reversing the fan rotation, 100 % outside air can be supplied. The reversible Buffalo Blower fan moves the same volume of air in both the supply and exhaust directions. The fan’s rotation is easily switched between supply and exhaust by using the optional reversing starter.

In large rooms, it is particularly effective to use several ventilators for summertime ventilation, using alternating units as supply fans and exhaust fans. All Buffalo Blower ventilators can then be arranged in this pattern for thorough coverage.

An integral part of Buffalo Blower Three-Way Heat Saver / Ventilator is Modulating Damper Fan Control package. The Modulating Damper Control package is designed to modulate one supply / exhaust fan damper, mounted horizontally at the roof curb level, and two recirculating fan dampers, mounted vertically on two sides of the fan’s plenum section. The three fan dampers are modulated to provide the right mix of recirculated air and outside air which reduces the heat load on the building’s heating system, lowering the building’s energy usage. The Damper Control package modulates the three fan dampers by using a discharge-air temperature-sensor, controlled from a remote set point. The dampers are modulated to maintain the temperature selected on the remote station. Modulating the fan dampers provides the right mix of recirculated air and outside air for supply, exhaust and recirculating operations. The control station is furnished as a separate part for remote mounting at the site. It houses the reversing starter switch for starting the fan and changing direction (reversing motor starter optional), and a temperature set point for temperature adjustments between 40° and 90°F. A mounting fan bracket for the discharge sensor is included for field installation at the fan plenum discharge.

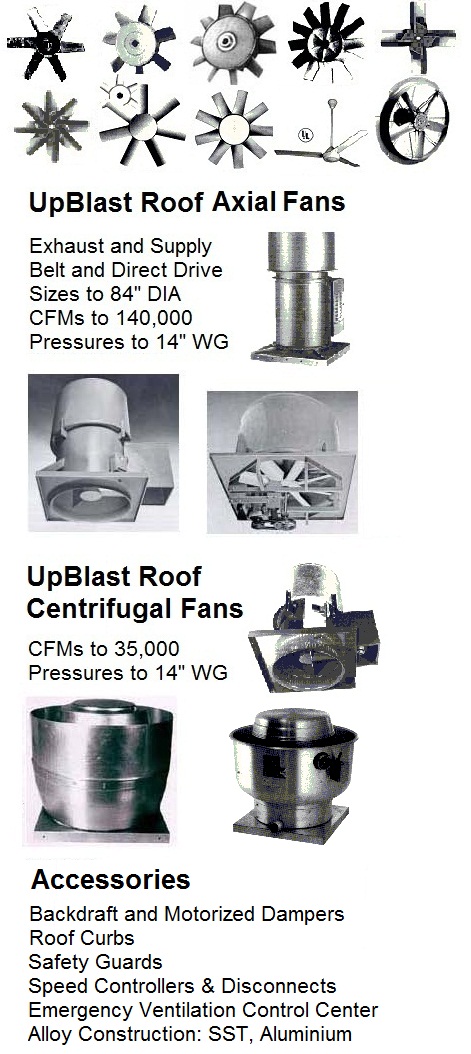

Canada Blower Upblast Roof Ventilator features a steel base plate welded to tubular steel struts to form a strong support for the motor and fan mounting base. All Upblast Roof Ventilators use statically and dynamically balanced airfoil fan propellers for optimal performance and longevity. The fan’s rolled steel circular windband cuts down on wind resistance and is easily removable for access to the motor and fan propeller. Fan flanges are integrally formed for increased strength. Upblast Roof Ventilator is constructed with close tolerances between the propeller tips and the exhaust orifice to take advantage of the propeller’s full area for maximum efficiency.

Canada Blower Upblast Roof Ventilator also features a set of free action, positive force dampers as standard. Fan dampers open automatically when the fan turns on and close when the fan is not running. During blower operation, discharge velocity prevents rain or snow from entering the fan. Air dampers for Canada Blower Upblast Roof Ventilator ride on rust free bearings to reduce maintenance and increase life. L2 blade and L4 blade propellers are used throughout the size range in both direct drive and belted fan models. Direct Drive Upblast Rood Fan uses steel construction as standard. Hot dip galvanized, stainless or all aluminum construction is optional. All fans are cleaned, chemically pretreated using a phosphatizing process and painted inside and out with a light gray enamel finish.

Industrial fans and pressure blowers, high temperature oven fans, high pressure blowers, centrifugal and axial blowers. Sales of regenerative blowers, high pressure ventilators, positive displacement pressure blowers.

ventilating.com fanblower.com highpressureblower.net industrialblowerfan.com industrialfanblower.net industrialfanblower.com pressureblower.net northernindustrialsupplycompany.com industrialpressureblower.com tenderall.com chicagoblowercanada.com cbblower.com buffaloblower.com buffalofan.com nis-co.com canadianblower.com olegsystems.com canadablower.com abbblower.com acmefan.net industrialblower.net fansandblowers.net americanblower.net barryfan.com cincinnatifan.net canadafans.com barryfan.net pennbarry.net pennfan.net tcffan.com