Presure Blowers

Radial bladed fans provide a

solution for a wide range of industrial applications. The heavy-gauge,

all-welded construction has earned it the reputation of being the

“workhorse” of the industry — a design proven by years of service

handling dirty, abrasive, sticky or bulky particulate-laden airstreams.

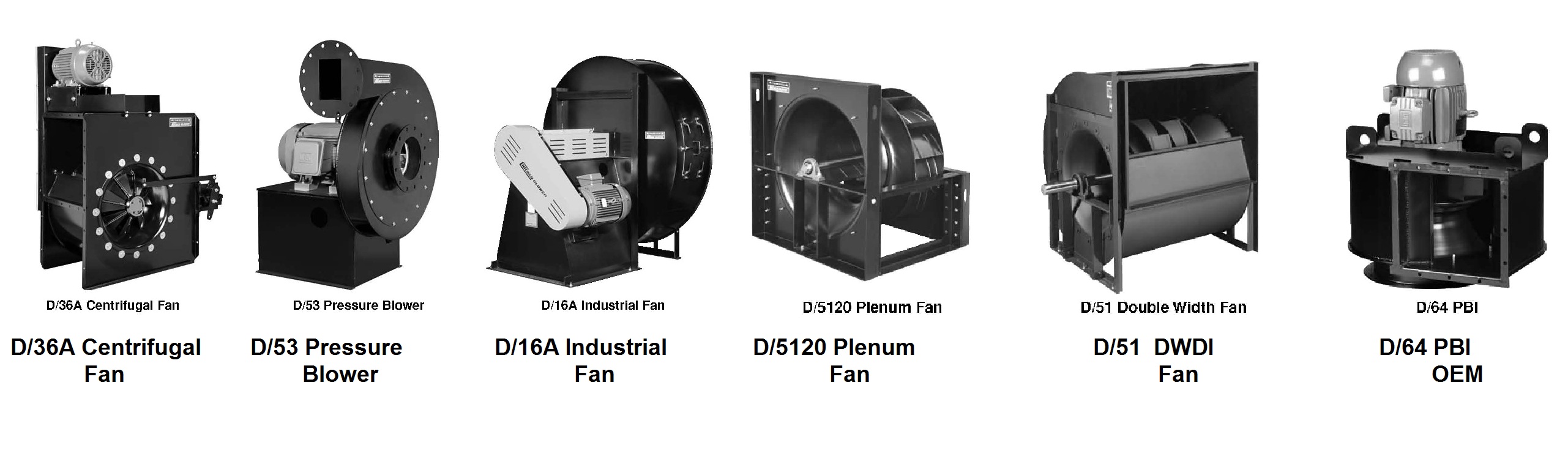

Centrifugal Pressure Blowers

Centrifugal High Pressure Blowers are supplied with heavy gauge housings and pedestals. Housings and pedestals are fabricated of heavy gauge steel, continuously welded and rigidly braced. They will stand up to rigors of strenuous duty, delivering smooth vibration-free performance. Removable inlet cover plate provides access to the wheel.

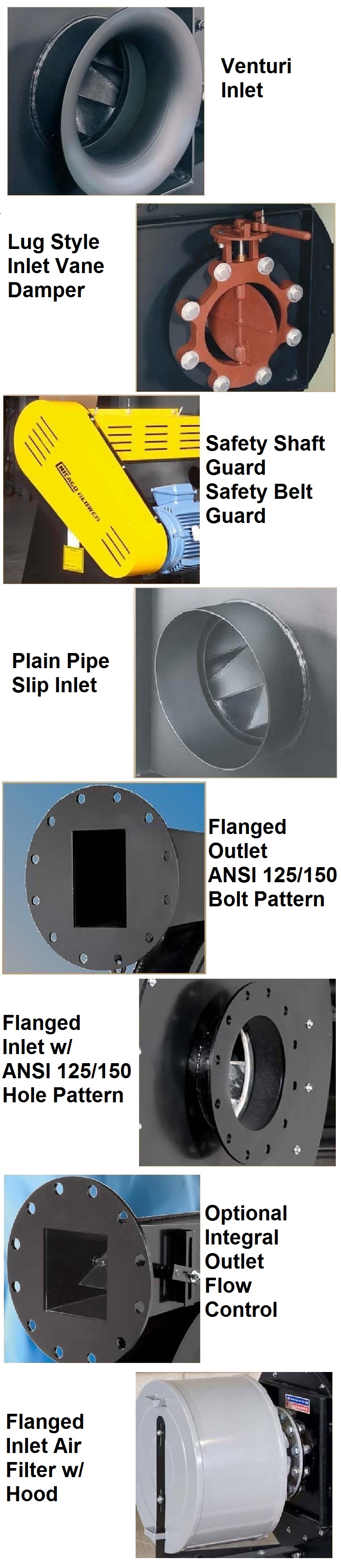

Radial Pressure Blowers are supplied with standard slip-fit inlet which facilitatets field mounting of either sleeves or flexible connectors. Flanged Inlets, or Venturi inlets are optional.

Shaft & Bearings used for belt driven Pressure Blowers are oversized for a critical speed at least b1.35 times maximum RPM of teh blower assembly. Bearings are heavy, industrial duty ball, or roller in cast iron pillow blocks.

High Pressure Blowers / Canada Blower utilize lightweight wheels of exclusive constant velocity design, made of aluminum alloy, which alows for sustantial load reducing on teh motor-drive components. The blades are positioned with precision fixtures and gas netal arc welded to teh spun aluminum side plates. The wheels are mopunted to the shaft with taperlock bushings.

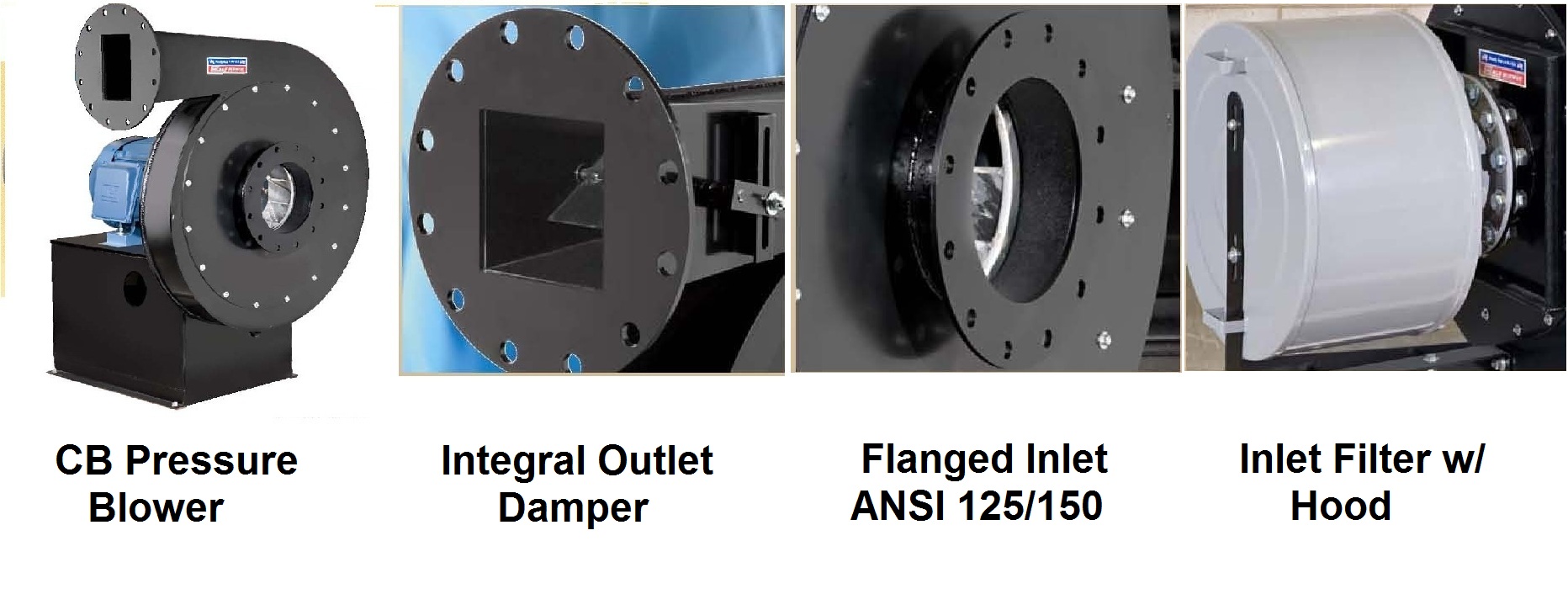

Flanged Outlets used on design 15 and Design 53 Pressure Blowers are standard, supplied with ANSI Class 125/150 pipe flange bolt holes and bolt circle to provide easy connection to flanged pipe. Outlets are continuously welded to the fan housing.

Inlet Filters for design 15 and Design 53 Pressure Blowers and Exhausters are available in two types paer and reusable wire mesh. Filter consists of an element, a base welded directly on teh fan inlet, and a lid held in place with wing nuts. Rain hoods and filter silencers are available.

Butterfly Valve Gate used on Design 15 and Design 53 Pressure Blowers is intended to fine tune performance or to vary the flow. The standard lug type mounts to the flanged fan inlet / outlet. A wafer type valve mounts between two matchiong flanges. Both types are controlled manually or with various actuators.

Outlet Slip Tube is bolted to the outlet flange of a standard schedule 40 pipe. Slip tubes with dimesnions for flexible hoses are available.

Flex-Sleeve is a specially designed rubber sleeve which forms a flexible connection to help to isolate the fan from vibrations elsewhere in the system. The 6" long sleeve is backed with a tough corded rubber cover held with stainless steel clamps.

Vibration Pads are made of low density cork and are designed to be mountyed between the fan pedestal and teh floor to reduce transmission opf vibrations.

Inlet Guard is fabricated of concentric rings and mounts on inlet venturi.

Venturi Inlet provides smooth flow into the wheel for optimum performance. Inlet venturi is required on open inlet blowers to meet catalog performance.

Flanged Inlet simplifies connection to a flanged piping. Flanges have ANSI Class 125/150 pipe flange bolt holes and bolt circle dimensions. The inlet flange is continuously welded to the inlet.

Guards & Extended Fittings Both options can be furnished on Arrangemnt 1, 8, and 9, to enclose shaft, bearings and couplings. The extended grease fittings permit bearing lubrication without removing the guards.

Shaft Seals reduce leakage around teh shaft where it passes through the housing. Shaft seals should not be considered as gas tight.

Discharge Elbows are needed on some downblast discharge models to allow discharge flange to clear the pedestal.

Special coatings and alloys used on Pressure Blowers are intended for corrosive applications.

Call

us today: 1-866-225-6937 E-mail: blower@industrialpressureblower.com

Canada Blower MHO Industrial Radial Paddle Fan: The open type radial paddle fan wheel design is extremely rugged using heavy-gauge steel components which are jig assembled for accuracy and consistency. All blower wheels are welded with care to insure the maximum in strength and reliability. MHO fan wheels are suitable for general handling of coarse, sticky, heavy, and / or abrasive materials.

Canada Blower MHR Industrial Radial Paddle Fan: The MHR wheel is similar to the MHO blower wheel, with the addition of end rings. MHR blower construction is standard on size 26 and larger Class 3 fans. MHR blower wheels are suitable for general handling of coarse, sticky, heavy, and/or abrasive materials.

Canada Blower MHA Industrial Radial Air Handling Fan: The MHA wheel is a more efficient type of blower wheel and is used when handling relatively clean air, fumes, vapor exhaust, and air with a light contaminant. The fan wheel is constructed with heavy-gauge blades welded to both backplate and front ring.

Canada Blower MHW Industrial Radial Backplate Wool Wheel: The MHW blower wheel is constructed to prevent paper shreddings, threads from buffing system exhaust, and other similar matter from hanging up on and wrapping around the spiders and fan blades. Fan applications include long, stringy or fibrous materials.

MHP Industrial Radial Paper Handling Wheel: This modified Canada Blower MHW fan wheel features trapezoidal gussets for the extra rugged construction necessary when handling corrugated paper trims, fibrous material, metal trim, and other high impact loading material. A paper deflector cone over the face of the hub helps prevent wrapping of paper around the hub or leading edge of the blower blades. All Canada Blower MHP fans are supplied with bearing stop blocks and a relieved inlet transition. The relieved inlet transition smooths the flow of paper trim and similar material through the fan.

A Radial fan is used for so many purposes these days whether that be for items found in most households or in cars or factories. They play an integral part in our everyday lives and will do so for many years to come.

Buffalo Blower is the industry-leading manufacturer of pulp and paper ventilation equipment - blowers and fans. Buffalo Blower provides maintenance-friendly, cost-effective, reliable fans that can withstand high moisture, highly corrosive

environments, as well as additional options for swingout and clamshell construction. This allows ease of access to clean and maintain the impellers and other internal components.

Buffalo Blower specializes in the following blowers, fans, ventilators:

• Swingout Roof Ventilators

• All Aluminum Construction

• 304 & 316 Stainless Steel Fans

• Fiberglass Fans

• High Temperature Fans – Options up to 500° F

• Corrosion Resistant Options

• High Moisture Modifications

• High Pressure Blowers

• Nominally Leak Tight Construction

• Clamshell Motor Covers

• Mancoolers

• Air Make-Up Units

Common Buffalo Blower Pulp & Paper Products and Features

• Swingout or clamshell – allows access to change bearings, impeller and shaft of fan

• Efficient maintenance turnaround means fast ROI

• Convenient access to lubrication lines

• Increased maintenance safety

• Minimized labor costs

• Minimized crane rentals

• Clamshell motor cover option for easy access to motor and motor sheave

Radial Bladed Fans with Paper Handling Impellers for

• General Ventilation and Employee Comfort

• Pulp Washers

• Paper Machine Exhaust

• Wet and Dry End Process Heat Control

Common Pulp and Paper Fan Applications are:

• Paper Trim Conveying

• Bleaching Process

• Replacement Parts / Retrofit Opportunities

Special Materials of Buffalo Blower Fans Construction

• Mild Steel

• Aluminum

• 304 & 316 Stainless Steel

• Fiberglass

Canada Blower is a world wide distributor of industrial process ans OEM fans and blowers, as well as fan components; including high pressure blowers, high temperature fans, spark resistant and explosion proof ventilators, tubeaxial and vaneaxial high pressure ventilators. Canada Blower also does existing fans and blowers repairs, re-build, as well as dynamical wheels balancing.

A radial fan is used in a large number of different industries, whether that be for the fan in your car or a fan in your computer to keep it from heating up too much. The word Radial means spreading out of a common centre which is how most fans work. They can also be used in large industrial type settings where there is a need to push either cooling air or just making sure there is air flow through a certain area.

Radial fans can also be known as a centrifugal fan, which is made up of three different types of blade settings. They are the straight steel plate paddle wheel, the forward multi-vane multi-blade and the backward turbo vane. They are also used in Industrial type situations such as factories, large underground carparks and gymnasiums. They can be used in lots of different situations where there are large enclosed open spaces which need some type of circulation, whether that be blowing cold air through the premises or to just have some sort of air movement. There are different types of fans, which can be put in an industrial factory such as a mounted fan or a freestanding fan. Obviously to do a large area you need a large fan so having it mounted can be a benefit whilst having it freestanding can also be a benefit because it can be moved if need be. There are also different noise levels of these fans but most fans these days are relatively quiet especially in an area such as a factory.

A radial fan is used in so many different ways and usually run by using electricity although a radial fan can also run off a generator. Most households have a radial fan, there is generally some sort of fan found in most houses. A radial fan can be just your normal portable fan or a ceiling fan is normal is most humid areas. When you do have a ceiling fan it's important to note that most of them must be put in by an experienced electrician otherwise you could have some serious problems with them. They are certainly a lot more economical than running an air conditioner, which is why they are so popular in humid areas where having some air flow cools down the place. Radial fans are also found in most air conditioning units now, they are used to blow cooled air out of the unit and into the room.

Canada Blower Clean Air Fans

Canada Blower offers a versatile selection of clean air fans for a broad range of industrial applications.

Airfoil fans are designed to move high volumes of clean air at low-to-medium static pressures. Airfoil fan blades are backwardly inclined and aerodynamically designed; one of the most efficient centrifugal fans.

Backward-inclined fans offer lower sound levels and energy costs in clean air applications; fan impeller designed for high operating efficiency and high mechanical strength in its specific blade angles.

Centrifugal plug fan is used in ovens and dryers to circulate clean air and eliminate cold spots; also good in dust collector applications.

ventilating.com fanblower.com highpressureblower.net industrialblowerfan.com industrialfanblower.net industrialfanblower.com pressureblower.net northernindustrialsupplycompany.com industrialpressureblower.com tenderall.com chicagoblowercanada.com cbblower.com buffaloblower.com buffalofan.com nis-co.com canadianblower.com olegsystems.com canadablower.com abbblower.com acmefan.net industrialblower.net fansandblowers.net americanblower.net barryfan.com cincinnatifan.net canadafans.com barryfan.net pennbarry.net pennfan.net tcffan.com